ZLFM Series Fixed Lifting Transfer Granulator

Classification:

Turn the whole granulator series

Key words: ZLFM Series Fixed Lifting Transfer Granulator

Product Description

Use

It is mainly used in the production process of solid preparations in pharmaceutical enterprises to transfer the granulated and dried solid materials from the hopper of the dryer. It is used with one-step granulator and boiling dryer to transfer the materials to the next process, effectively reducing dust and cross pollution, reducing labor intensity, and is an ideal material conveying equipment.

Product Features

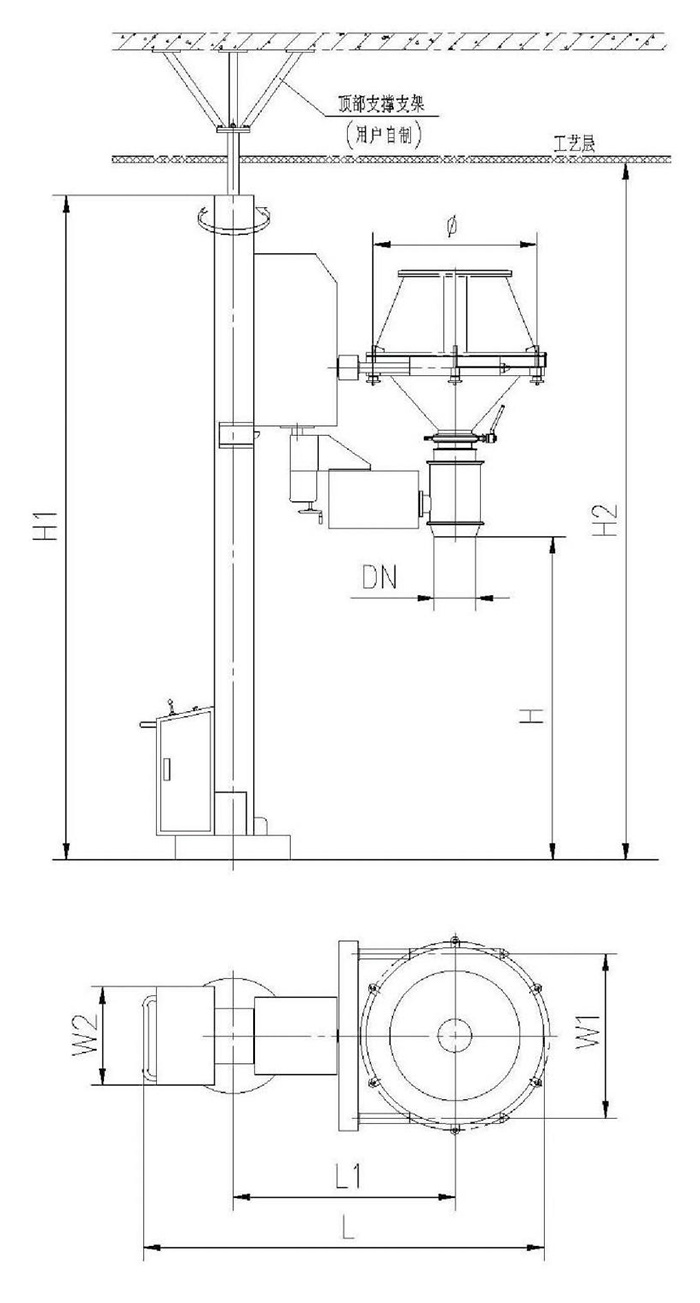

When working, fasten the cone hopper with the material bed (pot) of the one-step granulator (or dryer), lock the cone hopper, make the two buckle into one body, start the lifting button, and the silo is lifted; Start the turning button, the silo can turn 180 degrees. Open the unlocking button, horizontally rotate the column to the position required by the process, then lower the silo to the working height, open the granulator, open the butterfly valve, so that the material is transferred to the next process after being granulated.

Main technical parameters

| Model | Main structural dimensions | whole grain yield Kg/h |

Lifting load Kg |

Machine weight T |

Total power KW |

||||||||

| L | L1 | W1 | W2 | H | H1 | H2 | DN | φ | |||||

| ZLFM-200 | 2290 | 1200 | 1080 | 600 | 2000 | 4100 | 4300 | 250 | 1000 | 70-700 | 200 | 1.3 | 4.95 |

| ZLFM-300 | 2490 | 1300 | 1280 | 600 | 2000 | 4200 | 4400 | 250 | 1200 | 70-700 | 300 | 1.5 | 4.95 |

| ZLFM-500 | 2940 | 1650 | 1480 | 600 | 2000 | 4300 | 4500 | 250 | 1400 | 100-1000 | 500 | 1.6 | 4.95 |

| ZLFM-800 | 3140 | 1750 | 1680 | 600 | 2000 | 4400 | 4600 | 250 | 1600 | 100-1000 | 800 | 1.8 | 5.95 |

| ZLF-1200 | 3340 | 1850 | 1880 | 600 | 2000 | 4600 | 4800 | 250 | 1800 | 100-1000 | 1200 | 2 | 5.95 |

The company can customize production according to user requirements, if there is any change, without prior notice!

Previous Page

Next Page

Related Products

HLD Used in the mixing of granules and powder materials in the production of solid preparations, it is the most widely used mixing equipment in solid preparations. High charging coefficient and high mixing efficiency High mixing uniformity, and the hopper can be replaced, which is convenient for loading, discharging and cleaning, as well as sealing and transferring materials with the upper and lower process equipment to prevent material exposure and payment. Fork contamination Can be used in pharmaceutical, chemical food and other industries.

HTD Used in the mixing of granules and powder materials in the production of solid preparations, it is a widely used mixing equipment in solid preparations.

HDD Series Bin Blender, single arm is in appliance with PLC process controls inter-grade, is necessary device in mixing crafts of solid medical production mainly used in pharmaceutical industrial for mixing powder and granules, avoided dust and cross contamination and materials layering, optimized the producing flow.

HGD Series Square Cone Mixer is used in pharm aceutical industry mainly for mixing of guanules and powder, It gains the merits of large batch size proportional load supporting steady operation, etc Meanwhile, it can be widely used in such areas as raw medicinematerial industry, chemical industry, foodstuff industry, etc.

Product Consulting