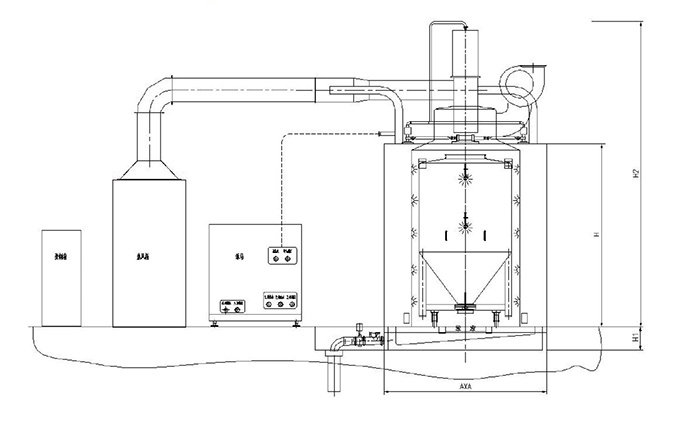

QXJ series automatic hopper cleaning machine

Classification:

Hopper cleaning machine series

Key words: QXJ series automatic hopper cleaning machine

Product Description

Use

This machine is suitable for automatic cleaning of stainless steel turnover containers containing powder, particles, capsules and other materials in pharmaceutical factories. It is equipped with a hopper cleaning machine to clean mixing hoppers or turnover hoppers of different specifications. It is an ideal equipment for cleaning containers in pharmaceutical factories. At the same time, it is widely used in pharmaceutical, chemical, food and other industries.

Product Features

1. The man-machine operation interface adopts touch screen, friendly interface, clear picture and convenient operation. High degree of automation, one setting can automatically clean the cleaning object thoroughly.

2, can automatically obtain the relevant records of equipment operation, easy to trace and certification of the production process.

3. The cleaning cost is reduced, and the consumption of cleaning agent, water and steam is small.

Compared with hand washing, it saves labor and improves the cleanliness of the container.

Main technical parameters

| Model | Main structural dimensions | Cleaning parameters | Drying parameters | Process conditions | ||||||||||

| A | H | H1 | H2 | Pump power | Flow | Pressure | Filtration accuracy | Air flow | Fan power | Steam | Compressed air | |||

| kw | T/h | Mpa | m³/h | kw | Bar | kg/h | Bar | L/min | ||||||

| QXJ-400 | 1600 | 1500 | 300 | 3100 | 2.2 | 4 | 0.4-0.6 | H13 | 2000 | 3 | 0.6 | 700 | 0.6 | 400 |

| QXJ-800 | 1800 | 1700 | 350 | 3400 | 3 | 4 | 0.4-0.6 | H13 | 2500 | 4.4 | 0.6 | 800 | 0.6 | 400 |

| QXJ-1000 | 2000 | 1800 | 350 | 3500 | 4 | 8 | 0.4-0.6 | H13 | 3000 | 5.2 | 0.6 | 900 | 0.6 | 500 |

| QXJ-1200 | 2000 | 1950 | 350 | 3800 | 4 | 8 | 0.4-0.6 | H13 | 3500 | 5.2 | 0.6 | 1000 | 0.6 | 500 |

| QXJ-1500 | 2000 | 2080 | 350 | 4100 | 5.5 | 12 | 0.4-0.6 | H13 | 4000 | 6 | 0.6 | 1100 | 0.6 | 600 |

| QXJ-2000 | 2000 | 2400 | 300 | 4700 | 5.5 | 12 | 0.4-0.6 | H13 | 4000 | 6 | 0.6 | 1300 | 0.6 | 600 |

The company can customize production according to user requirements, if there is any change, without prior notice!

Previous Page

Related Products

HLD Used in the mixing of granules and powder materials in the production of solid preparations, it is the most widely used mixing equipment in solid preparations. High charging coefficient and high mixing efficiency High mixing uniformity, and the hopper can be replaced, which is convenient for loading, discharging and cleaning, as well as sealing and transferring materials with the upper and lower process equipment to prevent material exposure and payment. Fork contamination Can be used in pharmaceutical, chemical food and other industries.

HTD Used in the mixing of granules and powder materials in the production of solid preparations, it is a widely used mixing equipment in solid preparations.

HDD Series Bin Blender, single arm is in appliance with PLC process controls inter-grade, is necessary device in mixing crafts of solid medical production mainly used in pharmaceutical industrial for mixing powder and granules, avoided dust and cross contamination and materials layering, optimized the producing flow.

HGD Series Square Cone Mixer is used in pharm aceutical industry mainly for mixing of guanules and powder, It gains the merits of large batch size proportional load supporting steady operation, etc Meanwhile, it can be widely used in such areas as raw medicinematerial industry, chemical industry, foodstuff industry, etc.

Product Consulting