HTD Series Column Hopper Mixer

Classification:

Hopper Mixer Series

Key words: HTD Series Column Hopper Mixer

Product Description

Use

HTD series column hopper mixer for the production of solid preparation of granular and powder material mixing, is the current solid preparation in the use of a wide range of mixing equipment. It has the characteristics of high charging coefficient, high mixing efficiency and high mixing uniformity, and the hopper can be replaced, which is convenient for charging, discharging and cleaning, and realizes sealed material transfer with the upper and lower process equipment. After mixing is completed, the hopper can be lifted to realize in-place sealed material separation to prevent material exposure and cross-contamination. Can be used in pharmaceutical, chemical, food and other industries.

Product Features

1. Automatically complete the lifting, mixing and lowering of the hopper to achieve fully sealed and dust-free operation.

2. The maximum hopper volume can reach 3000L, suitable for large-scale mixing, improving efficiency and saving costs.

3. Can replace the use of different specifications of the hopper, but also to adapt to small batch, multi-species production needs.

4. Touch screen operation, PLC control, control system adopts multi-level password management to ensure the safety of operation data.

5. The process parameters adopt formula management mode, and the system has the functions of data storage, fault alarm, data printing and so on.

6. Integrated gear motor drive, frequency conversion speed regulation, stable and reliable operation, easy maintenance.

7. After the mixing is completed, the hopper can be lifted to realize in-place sealed material distribution, with multiple functions in one machine.

8. Can be mounted on the wall to isolate the mixing area from the equipment area.

Main technical parameters

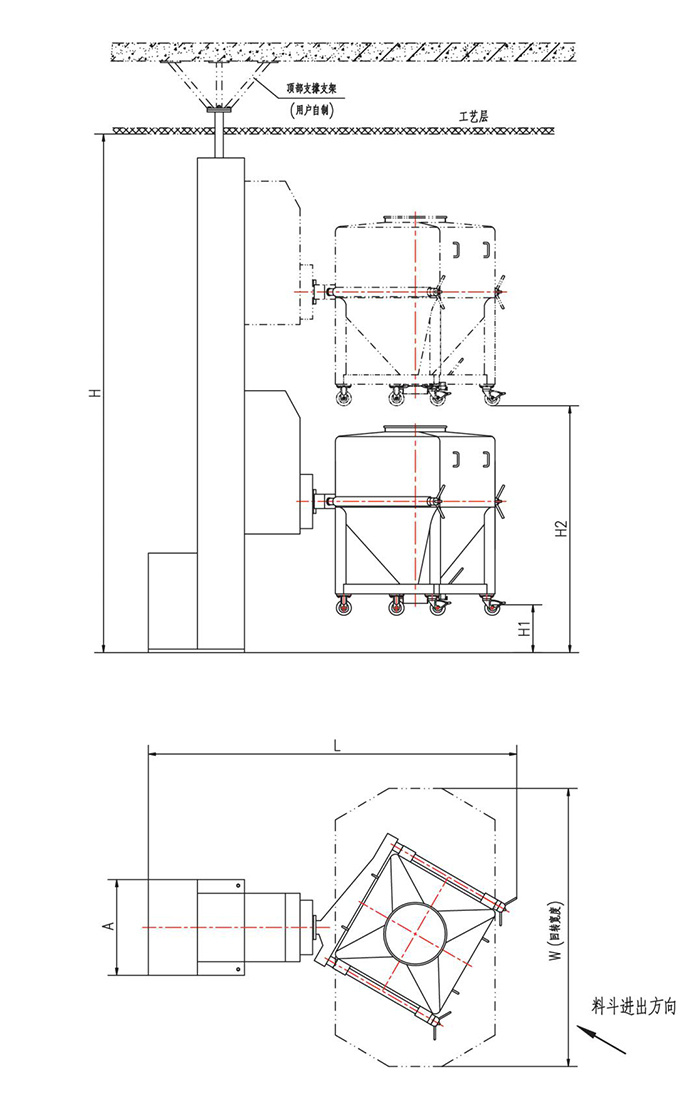

| Model | Main structural dimensions | |||||

| L | W | A | H | H1 | H2 | |

| HTD-50 | 2000 | 1100 | 650 | 1900 | 200 | 650 |

| HTD-100 | 2050 | 1200 | 650 | 1900 | 200 | 650 |

| HTD-150 | 2100 | 1350 | 650 | 2000 | 250 | 650 |

| HTD-200 | 2200 | 1800 | 800 | 2200 | 250 | 650 |

| HTD-300 | 2400 | 2000 | 800 | 2400 | 300 | 700 |

| HTD-400 | 2450 | 2050 | 800 | 2400 | 300 | 700 |

| HTD-500 | 2650 | 2170 | 800 | 2400 | 350 | 700 |

| HTD-600 | 2880 | 2300 | 800 | 2400 | 350 | 700 |

| HTD-800 | 3030 | 2400 | 800 | 2800 | 400 | 800 |

| HTD-1000 | 3120 | 2600 | 800 | 2800 | 400 | 800 |

| HTD-1200 | 2880 | 2300 | 800 | 3200 | 350 | 800 |

| HTD-1500 | 3030 | 2400 | 800 | 3500 | 400 | 1000 |

| HTD-2000 | 3120 | 2600 | 800 | 3800 | 400 | 1300 |

| HTD-2500 | 4125 | 3600 | 900 | 4000 | 600 | 1300 |

| HTD-3000 | 4260 | 3700 | 900 | 4000 | 600 | 1300 |

| Model | Maximum hopper volume L | Net Load kg | Mixing speed rpm | hybrid power kW | Boost power kw | Machine weight T |

| HTD-50 | 50 | 25 | 3-25 | 1.1 | 1.1 | 0.7 |

| HTD-100 | 100 | 50 | 3-25 | 1.1 | 1.1 | 0.8 |

| HTD-150 | 150 | 75 | 3-20 | 1.1 | 1.1 | 0.9 |

| HTD-200 | 200 | 100 | 3-20 | 1.5 | 1.5 | 1 |

| HTD-300 | 300 | 150 | 3-20 | 2.2 | 2.2 | 1.3 |

| HTD-400 | 400 | 200 | 3-15 | 2.2 | 2.2 | 1.4 |

| HTD-500 | 500 | 250 | 3-15 | 3 | 2.2 | 1.5 |

| HTD-600 | 600 | 300 | 3-15 | 3 | 2.2 | 1.7 |

| HTD-800 | 800 | 400 | 3-15 | 4 | 2.2 | 1.9 |

| HTD-1000 | 1000 | 500 | 3-12 | 4 | 3 | 2 |

| HTD-1200 | 1200 | 600 | 3-12 | 4 | 3 | 2.3 |

| HTD-1500 | 1500 | 750 | 3-12 | 5.5 | 3 | 2.9 |

| HTD-2000 | 2000 | 1000 | 3-10 | 5.5 | 3 | 3.5 |

| HTD-2500 | 2500 | 1250 | 2-8 | 7.5 | 3 | 4 |

| HTD-3000 | 3000 | 1500 | 2-8 | 7.5 | 3 | 4.5 |

The company can be customized according to user requirements,Subject to change without prior notice!

Previous Page

Related Products

HLD Used in the mixing of granules and powder materials in the production of solid preparations, it is the most widely used mixing equipment in solid preparations. High charging coefficient and high mixing efficiency High mixing uniformity, and the hopper can be replaced, which is convenient for loading, discharging and cleaning, as well as sealing and transferring materials with the upper and lower process equipment to prevent material exposure and payment. Fork contamination Can be used in pharmaceutical, chemical food and other industries.

HTD Used in the mixing of granules and powder materials in the production of solid preparations, it is a widely used mixing equipment in solid preparations.

HDD Series Bin Blender, single arm is in appliance with PLC process controls inter-grade, is necessary device in mixing crafts of solid medical production mainly used in pharmaceutical industrial for mixing powder and granules, avoided dust and cross contamination and materials layering, optimized the producing flow.

HGD Series Square Cone Mixer is used in pharm aceutical industry mainly for mixing of guanules and powder, It gains the merits of large batch size proportional load supporting steady operation, etc Meanwhile, it can be widely used in such areas as raw medicinematerial industry, chemical industry, foodstuff industry, etc.

Product Consulting